喷漆品质管理

喷漆品质管理

《喷漆品质管理》由会员分享,可在线阅读,更多相关《喷漆品质管理(32页珍藏版)》请在装配图网上搜索。

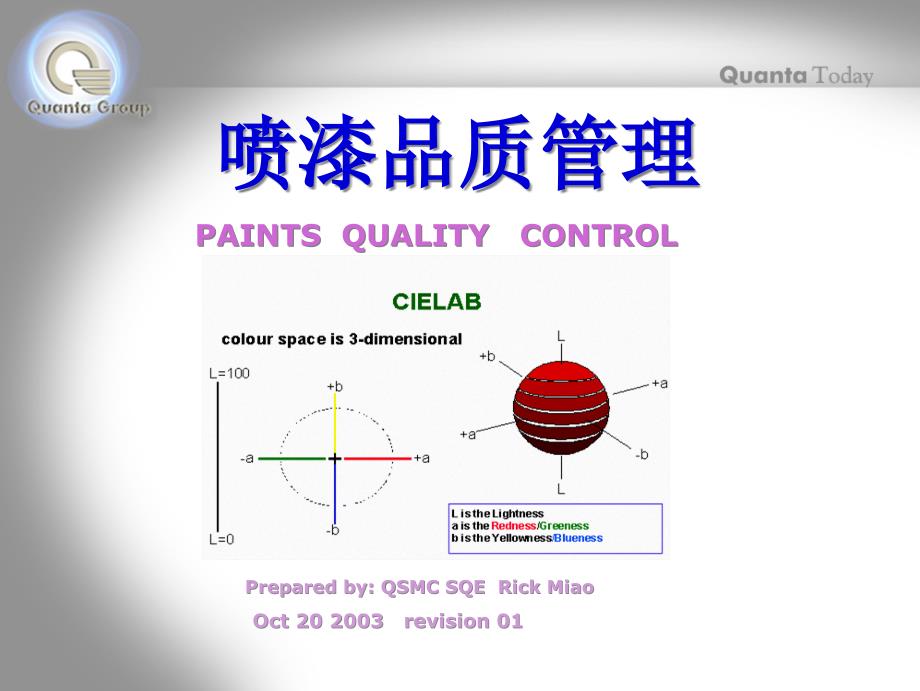

1、Click to edit Master title style,,Click to edit Master text styles,,Second level,,Third level,,Fourth level,,Fifth level,,*,,*,,,喷漆品质管理,PAINTS QUALITY CONTROL,,,,,,,Prepared by: QSMC SQE Rick Miao,Oct 20 2003 revision 01,,,,,试漆,,试产渐进生产计划,(,SLR ),PPAP,SIP,SOP,ready,送承认,量产渐进生产计划,(SLM),,RTS,量产,喷漆

2、量产前管制流程,稳定量产,直通率目标量产点检,,漆厂线上稽核,,,量产,SL,-,制程不良,P-chart,SQRC Review,,,试漆报告,CPK report,,,调漆及喷漆参数标准,PMP,SIP and SOP,试产前,SL,喷漆稽核,点检,喷漆周月报,-直通率目标,-周月品质改善,(3up chart and,painting monthly report,ISSUE,异常处理,-,DELL 5C report,-TFC SCAR,-LESSON LEARN,喷漆品质系统管理,喷漆制程管理流程,Thickness CPK,building,,Color match CPK,bui

3、lding,Safety launch building,,----co-work with paints suppliers try thickness Spec and CPK in.,--Trial run units min. 30pcs,--Fix the painting parameter.,----Painting applicators take care.,--Trail run min. 100pcs for yield rate,-- Yield rate meet target.,--Top 5 issue with FA and CA.,--co-work wit

4、h paints suppliers try,Painting color with tints adjustment,to in Spec.,--Trial run units min. 30pcs.,--Fix the painting tints ratio.,--Painting suppliers take care.,,,,,--co-work with paints suppliers try color and Thickness CPK >1.33.,--Trial run min. 3 lots(each lots 30pcs),--QSMC SQE involve eac

5、h CPK report,Review.,--All reliability should be passed.,,Painting Applicators Trail run process flowchart,Yield rate,building,,,CPK Continues,Trial Run building,--.color and thickness Spec and CPK. in,--.reliability testing passed.,--.yield rate can support RTS.,Trail run ok,--Before RTS 3K,trial r

6、un safety launch,-- After RTS 5K,MP safety launch.,-- Safety launch with issue highlight.,with FA and CA per day.,试漆,PROCSS,流程,Spec.,,PMP creation,Safety launch building,,----Color chip,----PDS and Cosmetic & testing Spec.,----Painting ratio viscosity Spec.,--Trail run min. 100pcs for yield rate,--

7、Yield rate meet target.,--Top 5 issue with FA and CA.,--Based on trail run result create,PMP.,--Painting ratio and viscosity parameter.,--FAI and IPQC check items.,--Flash time & oven temp. and time.,--Painting parameter.,--Reliability testing and color & film building.,,,,,--Co-work with TFC IQC to

8、 create SOP and SIP,--Customer Spec. and QC and process key point.,Painting Applicators Trail run system flowchart,Yield rate,building,,,SIP and SOP creation,--.color and thickness Spec and CPK. in,--.reliability testing passed.,--.yield rate can support RTS.,Trail run ok,--Before RTS 3K,trial run

9、safety launch,-- After RTS 5K,MP safety launch.,-- Safety launch with issue highlight.,with FA and CA per day.,试漆,SYSTEM,流程,Supplier Paint Safe Launch Status,Example of Reporting format,Corrective Action Tracking Log,Example of Reporting format,,,,Painting PMP,,,-The FPY targets are defined for each

10、 process and stages:,,-,SLR (Safe Launch Ramp) since system pilot build Mass production,,,,,,Build stage,,,,SLR(Q’ty:3K),,,,Mass production(Q’ty:5K),,,,Forming process,,,Injection,,,95.00%,,,96 .00%,,,Pressing,,,85.50%,,,90.00%,,,Die-casting Al/Zn/Mg,,,90%/90%/79%,,,95%/95%/87%,,,,Painting process,,

11、,Painting-plastic,,,86.00%,for one pass,,,88.00%,for one pass,,Painting-Metal/Mg,,,78.90%/75%,for one pass,,,83.00%/83%,for one pass,,,,Sub-ass’y process,,,Sub-ass’y(incl. Heat staking, gluing, etc.),,,96.00%,,,98.00%,,,,,,,,,,,,,2,nd,Tier Supplier Quality Gate of New Tooling,,Safety launch quality

12、goal,,,,,喷漆测试项目,SPCE,,,,喷漆量产前点检表,,,,Painting CPK report,,,,涂装试作参数记录,,,,,试漆报告,Dell,2K Monocoat with two applications,Operation Guide – Plastic,Pretreatment,2k Monocoat,DFT ≒ 10-15um,Baking,(30 mins@60C),,Baking,(30 mins@60C),,Packing,flash,Flash,,All information is given in good faith but users must

13、satisfy themselves that there are no,circumstances requiring additional information or precautions or the verification of details given,,EH10/02,,2k Monocoat,DFT ≒ 10-15um,Inspect,Defect,Yes,No,Yes#,No,2000,grit,sanding,Inspect,Defect,#This step is only allowed one time. If part is still defectiv

14、e after passing through the second application station,twice,, the part must be scrapped.,Total DFT will range from 20-45 microns.,Paints process flowchart,Dell,2K Monocoat with one Application,Operation Guide – Plastic,Pretreatment,With Mineral Spirits,2K Monocoat,DFT ≒ 20-30um,Baking,(,30mins@60C

15、,),Substrate Temp.,,flash,,All information is given in good faith but users must satisfy themselves that there are no,circumstances requiring additional information or precautions or the verification of details given,,EH10/02,,Scuff Sanding,With 2000grit,Clean,NO,Yes,Inspect,Defect,Package,No more t

16、han 1 time rework;,Total DFT 20-60 microns;,Dell need to confirm total DFT.,4. The process will be modified based on line condition.,,3-5,mins@Ambient,Cool Down2 Hrs later,4-48,hrs later,,XPM60360S:XPH80002:M850-59572,=4:1:1,Viscosity: 12—18 Seconds NK2#,Issue #,:,Issue Title,:,Date:,,Descriptio

17、n,:,,,Champion,:,,Containment,:,,,Root Cause,:,Corrective Action,:,Preventive Action,:,Verification:,,described sheet-,,,Characterize,Contain,,Cause,,Corrective Action,Closure,Blank form example,,,Green = Completed,,Yellow = Currently Working,,Red = Future Work,5C report,Blank form example,3-up Cha

18、rt,Blank form example,3-up Chart,柏拉圖月報也應填寫妥當並指出哪些問題點尚未解決.,這樣的方式將有助於確立方向使行動有所進展.,3-up chart,Blank form example,炉温曲线,Sample,30,分钟,Blank form example,漆厂漆技术产品资料,Blank form example,漆厂漆技术产品资料,Blank form example,漆厂,LINE SUVERY,,,,喷漆量产前点检表,,,,量产前,Building,系统,SQRC Review,Blank form example,P-chart Control,Bl

19、ank form example,品质不良分析流程,Blank form example,Lesson learn(,经验互享),,谢谢观看,/,欢迎下载,BY FAITH I MEAN A VISION OF GOOD ONE CHERISHES AND THE ENTHUSIASM THAT PUSHES ONE TO SEEK ITS FULFILLMENT REGARDLESS OF OBSTACLES. BY FAITH I BY FAITH,内容总结,喷漆品质管理。PPAP,SIP,SOP。-制程不良P-chart。PMP,SIP and SOP。(3up chart and。-DELL 5C report。to in Spec.。--.reliability testing passed.。Die-casting Al/Zn/Mg。95%/95%/87%。88.00%for one pass。Sub-ass’y(incl. Heat staking, gluing, etc.)。DFT ≒ 10-15um。=4:1:1。Viscosity: 12—18 Seconds NK2#。Verification: described sheet-。Blank form example。谢谢观看/欢迎下载,

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

最新文档

- 2025年水电工程运行维护管理合同示范文本.docx

- 2025年工程勘测设计合同模板.docx

- 2025年区域产品销售代理合同.docx

- 2025年经销商授权合同样本.docx

- 2025年员工住房资金借贷合同.docx

- 2025年轻钢建筑施工合同示例.docx

- 2025年网络推广托管合同.docx

- 2025年简明个人借款正式合同范例.docx

- 2025年房产按揭贷款合同范例.docx

- 2025年技术合同争议调解.docx

- 2025年电子版城市住宅租赁合同范本.docx

- 2025年简易转让合同协议书样本.docx

- 2025年投资顾问服务合同实例.docx

- 2025年经销合同模板.docx

- 2025年工业项目设计合同样本.docx